Concrete Floor Screed Ratio

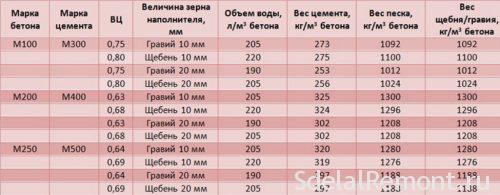

You can also estimate the quantity of sand and gravel required by weight.

Concrete floor screed ratio. How to calculate the proportions of sand and dry mix for the floor. For what i do residential light commercial concrete floors slabs patios driveways pool decks and walkways i think the 2 best screeds are the 2x4 magnesium or aluminum ones and the vibratory screeds. Our mix on site concrete calculation is based on batching by volume large construction sites employ batching by weight which is more exact. Determining the number of materials for screed a very important issue.

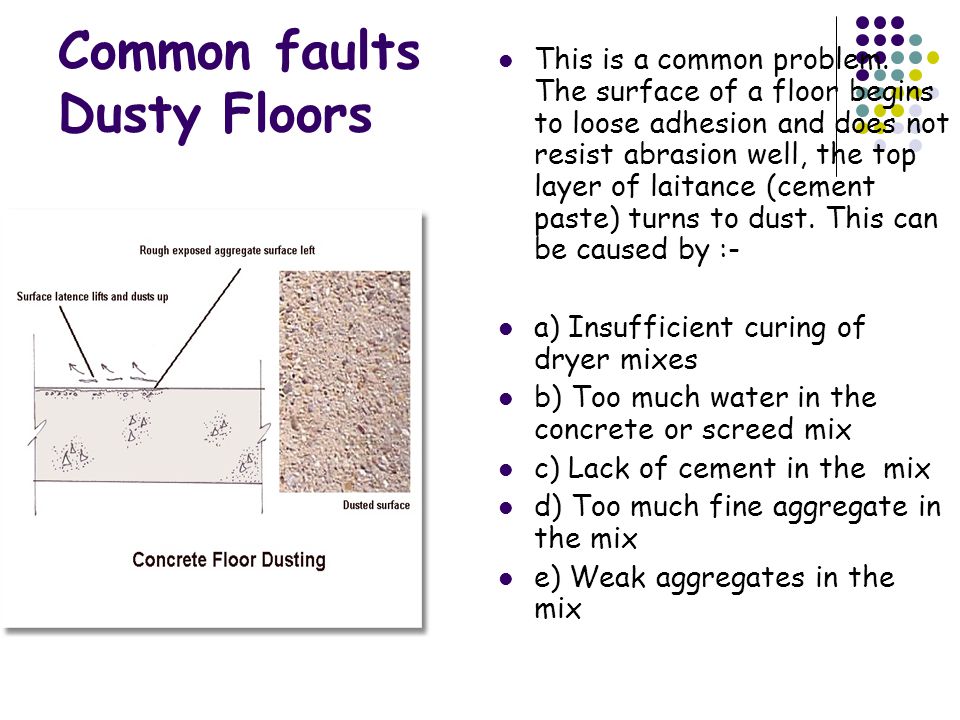

The strength of this mix ratio is good for most concrete slabs footings steps and foundation walls. And same is suitable for use in hospitals schools hospitals. Added to that cement type grade of aggregate and the method of storage of screed material influence the mix ratio to a certain extent. I ve used wooden 2x4 s and 2x6 s magnesium 2x4 screeds magnesium 3 4 x 4 screeds vibratory screeds and laser screeds.

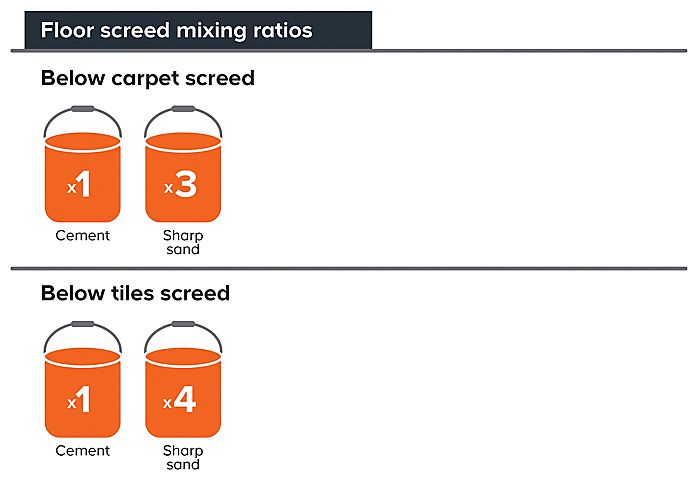

Traditional screeds are generally suitable for use in hospitals schools hospitals retail homes etc. One of the best concrete mix ratios is 1 part cement 3 parts sand and 3 parts aggregate this will produce approximately a 3000 psi concrete mix. What is the ratio for mixing concrete. The standard screed mix of cement and sand mixed in the ratio of 1 3 5 is used for creating a defined layer for installing the final floor finish such as tiles wood linoleum vinyl etc.

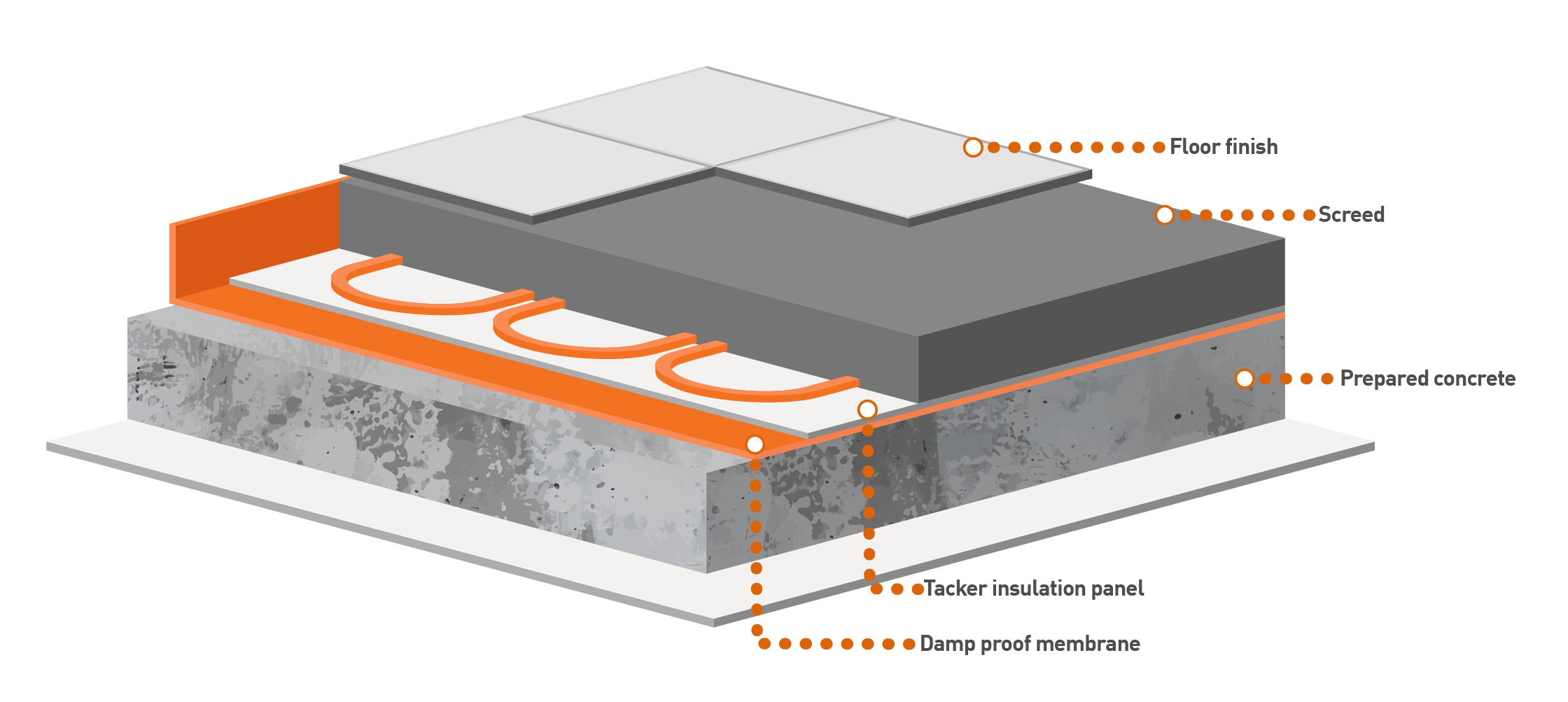

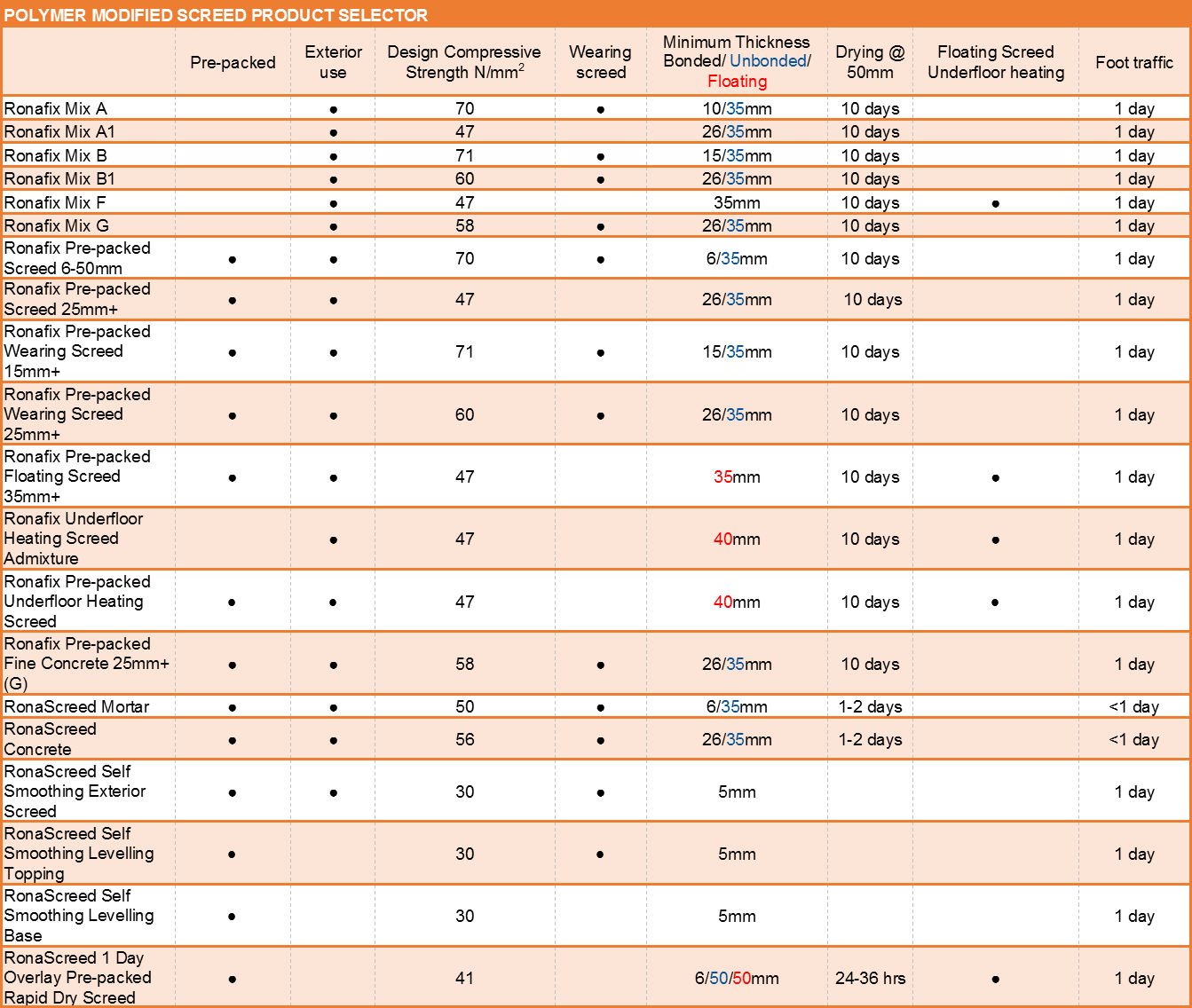

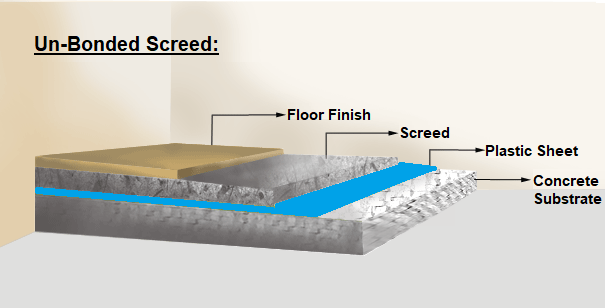

There are many proprietary screeds on the market and information about these can be obtained from the manufacturer. It may be applied onto either a solid in situ concrete ground floor slab or onto a precast concrete floor unit. Simply multiply the volumetric quantity of sand and gravel with 1400 kg m 3 bulk density of sand and 1600 kg m 3 bulk density. Screed is usually applied on top of the concrete slab and is most commonly used as a finishing layer on internal floors or to level the floor prior to final floor coverings carpet tiles natural stone linoleum wood flooring resin coatings etc.

What is the cement consumption per 1 m2 of screed. The standard mix of cement and sand mixed in the ratio of 1 3 1 4 and 1 5 for creating a defined layer for installing the final floor finish such as tiles wood linoleum vinyl etc. A floor screed is usually a cementitious material made from a 1 3 or 1 4 5 ratio of cement to sharp sand.