Concrete Floor Topping Specification

Placing and finishing the concrete floor to acceptable standards is impracticable.

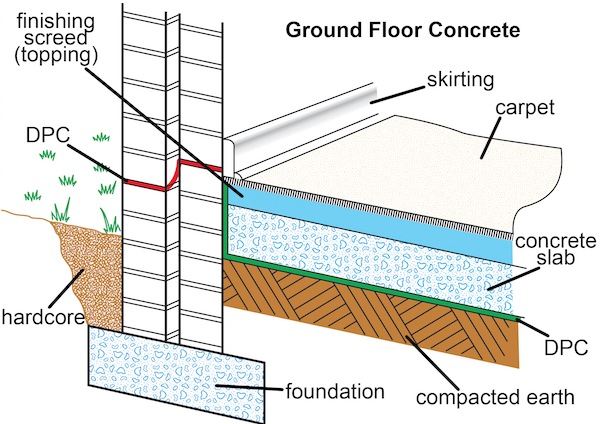

Concrete floor topping specification. Wet cure concrete topping for seven days covering the slab with concrete curing cover materials or curing blankets. These floors are constructed for different purposes but the reduction of dead loads on the structure is. Concrete topping 03 53 00. Ardex k 301 exterior self leveling concrete topping is a self leveling topping and underlayment for fast track resurfacing and smoothing for exterior and interior applications over concrete and approved properly prepared non porous surfaces including terrazzo epoxy coatings and ceramic and quarry tile on above or below grade.

They are particularly useful for heavy loads or traffic or when combined with underfloor heating for continuous and efficient space heating. Application over pre set concrete. The reduced quantity of concrete and steel reinforcement offsets the marginally higher cost of lightweight concrete floor systems. 2008 reed construction data.

And concrete toppings for floors 3. Existing concrete floors with damaged finishes over wood floor systems. Floor top stg is a standard traffic grade single component shrinkage compensated self leveling floor topping and underlayment that may be pumped or poured. The ten part spec data format conforms to the editorial style of the construction specifications institute and is used with their permission.

Concrete topping slab is an overlay designed to provide a dense abrasion resistant and a finished floor surface for multiple purposes such as providing a wearing course to support traffic loads in parking facilities and bus terminals providing a level surface for interior floors providing special base for electrical and mechanical equipment and to resurface worn. Floor top stg is specially designed to smooth out uneven rough or minor deteriorated interior concrete floors. After seven days remove cover curing allow to dry and then continue curing with two coats of high solids astm c 1315 conforming l m dress seal wb 30 curing and sealing compound. 8 4 finishing class 1 2 and 3 floors 8 5 finishing class 4 and 5 floors 8 6 finishing class 6 floors and monolithic surface treatments for wear resistance 8 7 finishing class 7 floors 8 8 finishing class 8 floors two course unbonded 8 9 finishing class 9 floors 8 10 toppings for precast floors 8 11 finishing lightweight concrete.

Lightweight concrete floor provides more efficient strength to weight ratio in concrete floor systems when compared to other conventional concrete floor systems. Exposed concrete floors are durable hard wearing and useful for all sorts of applications from warehouses to art galleries and garages to domestic living rooms. Screeds the surface of the screed should be finished according to the type of wearing surface or flooring that is to be laid.