Cone Rating For Firing Ceramics

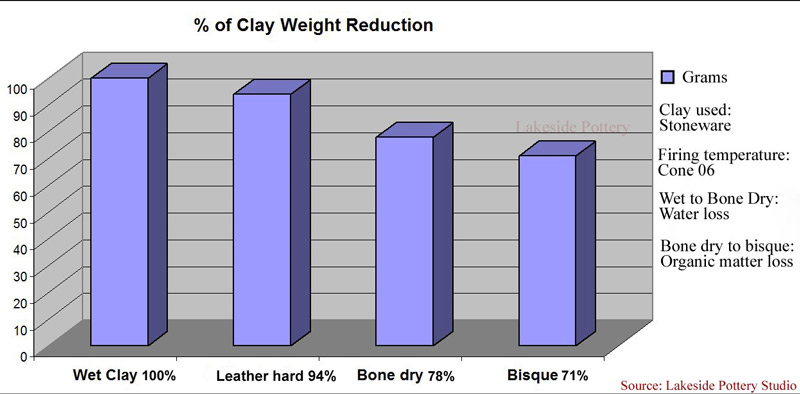

First it is important to know that the maximum cone rating of a stoneware or porcelain clay is the temperature at which it vitrifies.

Cone rating for firing ceramics. In general the following cones are used in the pottery studio. Pyrometric cones are designed to deform at certain moments during a firing. We recommend always buying a kiln that is specified for a higher temperature than you plan to fire. These cones are used in firing porcelain floor tile china stoneware structural clay products and some refractory materials.

This deforming action allows the kiln to shut off automatically at the proper point as in the case of the mini bar and kiln sitter or simply to record what happened during the firing as in the case of the witness cone. Numbers 13 to 42 these cones are used for firing industrial products up to 3659 f 2015 c. If you plan to fire mostly to cone 6 or 8 a regular cone 10 kiln. Cone 015 to cone 07 cone 013 approx.

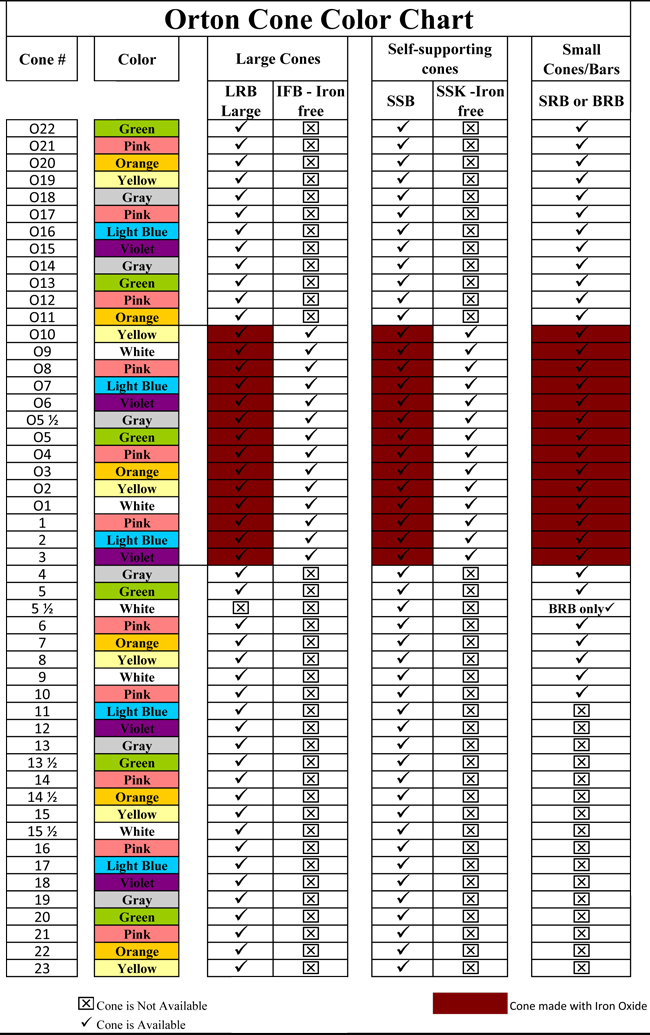

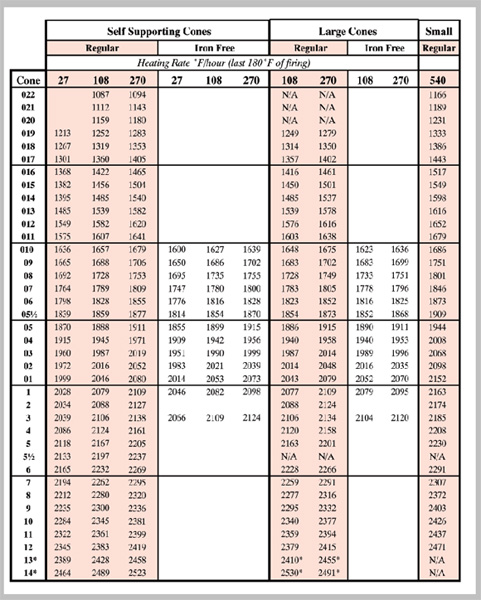

1566 f 850 c cone 012 approx. Low fire earthenwares and lowfire lead glazes mature. Cone temperature conversion chart. Cones are made from various oxide mixtures and bend at known temperatures.

The temperature range is approximately 2175 to 2345 f 1180 to 1340 c. When i first started working with ceramics without thinking i just figured that. 2048 f 1120 c this range is usually used for luster glazes and very low firing overglazes. Ware and glaze types.

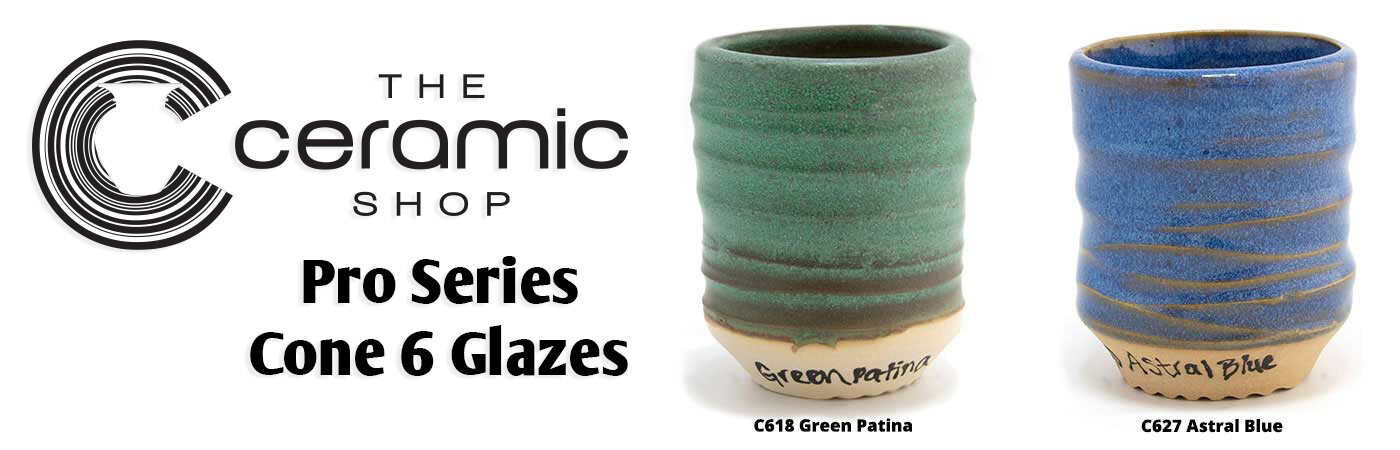

There has been a fairly prevalent belief in the ceramics world that cone 6 electric ceramic glazes are boring. It is very important to know what type of clay you are using so that the right cone is used. Just following the rules instead of testing and learning. 1623 f 882 c cone 02 approx.

Your ceramic ware provider can provide guidance on which cone to fire to for your specific ware. Firing clay using pyrometric cones. Normal firing temperature for red bricks and terra cotta pots. Bisque fire cone 08 05 low fire cone 06 04 mid range cone 4 7 and high fire cone 8 10.

We get many questions about clay firing temperatures. This is the hardening tightening and finally the partial glassification of the clay. People want to know if they can fire a certain clay to a certain cone. 04 is the extreme end of the bisque range i know some people may bisque a little higher i have and once again not only is cone 06 or lower a better cone to fire to for most purposes 06 08 010 save time wear on the kiln energy money studio comfort and the environment.

Less than 5 of people with electric kilns actually fire them to cone 10 but in case you are looking to fire to cone 10 all the time please read our tip 106 on true cone 10 kilns to help you pick the right kiln. Using the wrong cone can prove disastrous and expensive for a whole kiln load of ceramics or pottery and even destroy your kiln. Stoneware glaze some decals fire to cone 10.