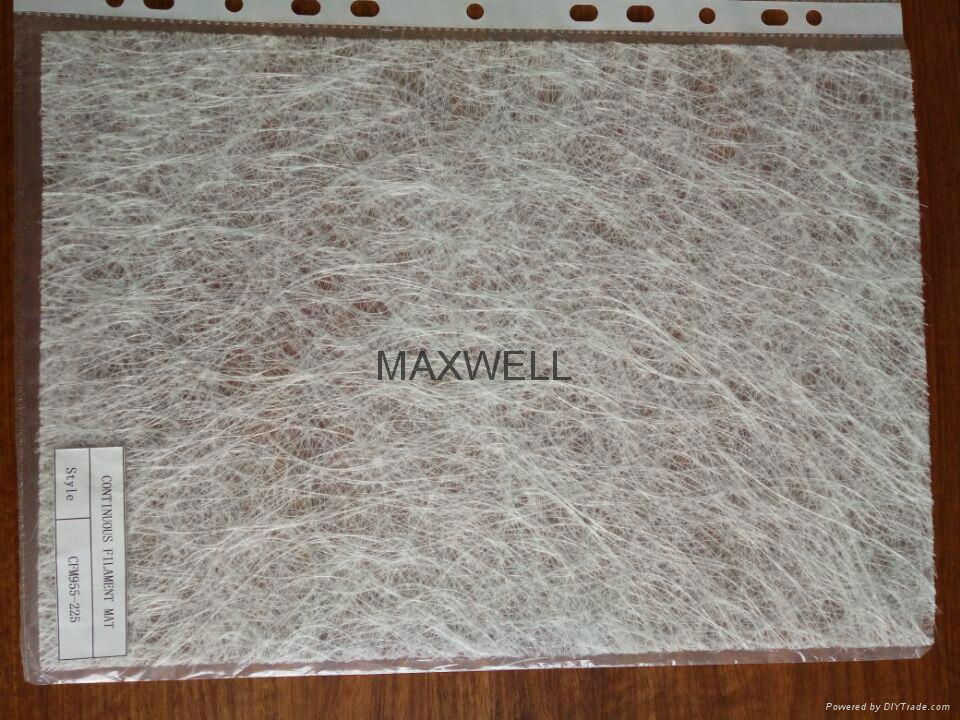

Continuous Strand Mat

Production process of frp boat mould.

Continuous strand mat. Enter your email address to subscribe to our newsletter subscribe you have been successfully subscribed to our newsletter subscribe you have been successfully subscribed to our newsletter. Chopped strand mat is produced by chopping continuous strand roving into short 1 5 to 3 inch lengths and dispersing the cut fibers randomly over a moving. Continuous filament mat is produced by dispensing molten glass strands directly onto a moving belt in a looping fashion. A first in first out fifo stock.

Chopped strand mat csm is a random fiber mat that provides equal strength in all directions and is used in a variety of hand lay up and open mold applications. Continuous strand mat this mat is sold by the linear yard either as a prepackaged quantity or by continuous yardage. Mat is great for molds or parts where thickness is needed. No 251 jianye avenue weiyuan county neijiang sichuan china.

Generally all fiberglass mat including the mat tape is used in a schedule with other fiberglass fabrics. Chopped strand mat is made up of short randomly oriented strands of fiber that are held together with a styrene binder. Continuous filament mat 3b s continuous filament mat cfm is a non woven mat made from 3b e cr glass filaments consisting of continuous fibres randomly orientated in multiple layers. While chopped and continuous strand mat are often used as inner layers to build bulk fiberglass veil mat is used at the surface to prevent show through of other fiberglass fabrics below.

Chopped strand mat csm is a widely used traditional reinforcement solution. Why chopped strand mat is often used. Continuous filament mat also known as continuous strand mat is a randomly orientated fiber that differs from chopped strand mat because of continuous long fibers rather than short chopped fibers. Protect product from all sources of water at all times.

The glass fibre is bonded with a silane coupling agent and the layers held together with a suitable binder. Product information storage these products should be stored in a dry area with ambient temperature and relative humidity optimally from 20 c to 25 c and between 50 and 70 respectively.