Contraction Joints In Concrete Floors Uk

Contraction joints are the most common type of joint in concrete pavements thus the generic term joint generally refers to a contraction joint.

Contraction joints in concrete floors uk. Temperature changes make concrete expand and contract. Dry cut joints should be made between 1 to 4 hours after completion of finishing. Contraction joint is placed in such a way that it interferes least with the performance of the structure as well as prevents formation of objectionable shrinkage cracks elsewhere in concrete. Both isolation and construction joints are formed before the concrete is poured.

Contraction joints are typically installed with jointing tools while the concrete is still plastic or by sawing after the concrete has been finished with either a wet cut saw or more commonly an. The gaps in concrete are known as control joints or expansion and contraction joints and they are there for a substantial reason. Saw cut joints should be done within 4 to 12 hours after the concrete has been finished. Contraction joints or control joints are placed in the fresh concrete before it has a chance to create its own joints also known as cracks.

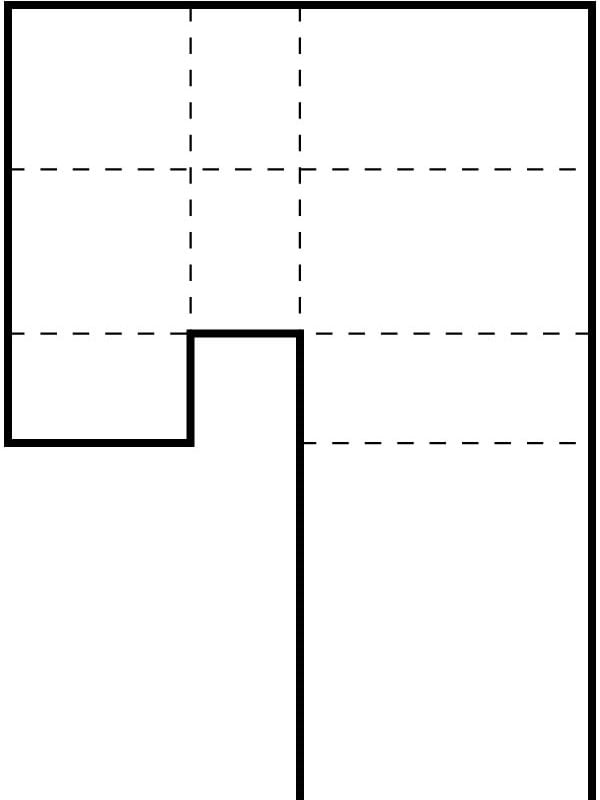

Table 2 suggests joint spacings for various pavement thicknesses. It is also important to keep slabs as square as possible. Crack control joints are a partially formed contraction joint that aims to ensure that when the concrete does crack it cracks in a predictable manner at a precise location. A fresh concrete mixture is a fluid plastic mass that can be molded into virtually any shape but as the material hardens there is a reduction in volume or shrinkage.

They are generally between 1 4 1 3 the depth of the slab and typically spaced every 3 1 15 m. Structures are designed with expansion and contraction joints at appropriate places to allow this movement to take place. These joints are placed in the slab as an allowance space for concrete expansion. When using joint groove for contraction joints the joint should be a minimum depth of thickness of the slab.

What a contraction joint really is in the end is a crack in the slab that we force to follow a line of our own choosing. Contraction control joints are placed in concrete slabs to control random cracking. Transverse joint spacing should not exceed 125 to. The concrete expands into the floor joints which relieves the pressure.

The design of the joint is important for the overall design to function correctly. Keyed joints are not recommended for industrial floors. Construction joints although this type of joint is not a true movement joint it is a commonly formed joint in concrete construction and so is included here for completeness. What is contraction joints.

Dowels are used to transfer shear across construction and movement joints in concrete.