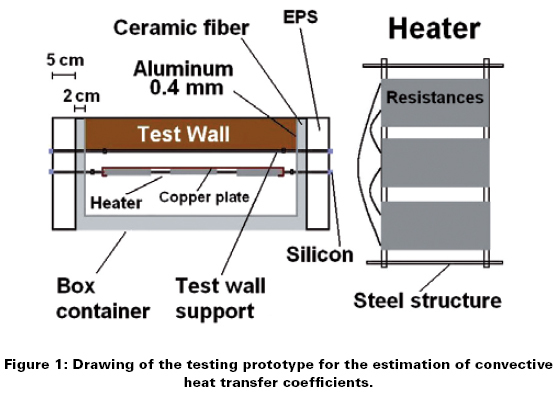

Convection Coefficient For Ceramic

The heat transfer coefficient has si units in watts per square meter kelvin.

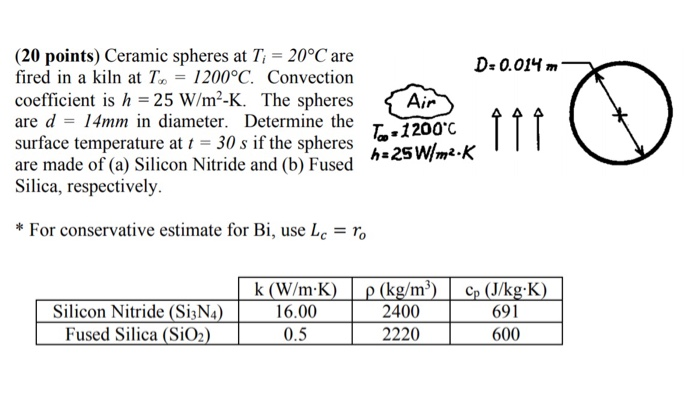

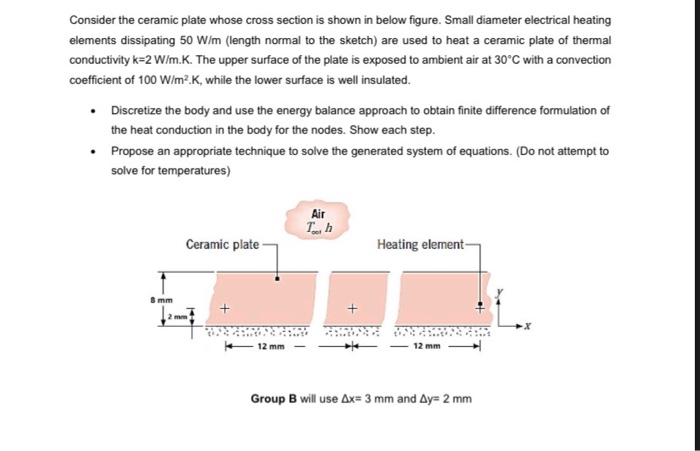

Convection coefficient for ceramic. Typical values of heat transfer coefficient. The heat transfer convection coefficient for air is 50 w m 2 k. The overall heat transfer rate for combined modes is usually expressed in terms of an overall conductance or heat transfer. The surface temperature is 50oc the fluid temperature is 20oc and the convective heat transfer coefficient is 2000 w m2oc.

It is an experimentally determined parameter whose value depends on all the variables influencing convection such as the surface geometry the nature of fluid motion the properties of the fluid and. The convective heat transfer coefficient is dependent upon the physical properties of the fluid and the physical situation. Inside temperature in the exchanger is 100 o c and outside temperature is 20 o c. For example sahai and overfelt 1995 give values of around 300 w m 2 k for cylindrical geometries and of 50 5000 w m 2 k for plate geometries of the nickel based superalloy in718.

The convective heat transfer between the hotter surface and the colder air can be calculated as. U 1 1 h ci s k 1 h co 3b the overall heat transfer coefficient for heat exchanger in. Heat transfer coefficients it is used in calculating the heat transfer typically by convection or phase transition between a fluid and a solid. Convection is the transfer of heat due to the bulk movement of molecules within fluids gases and liquids including molten rock convection includes sub mechanisms of advection directional bulk flow transfer of heat and diffusion non directional transfer of energy or mass particles along a concentration gradient.

Hui li ph d p e in pavement materials for heat island mitigation 2016. The heat transfer coefficient or film coefficient or film effectiveness in thermodynamics and in mechanics is the proportionality constant between the heat flux and the thermodynamic driving force for the flow of heat i e the temperature difference δt. The overall heat transfer coefficient u per unit area can be calculated by modifying 3 to. The heat transfer coefficients between 430 and 560 w m 2 k are within the range of values published in literature for nickel based superalloy melts in contact to ceramic shell molds.

Ceramic materials are very good electrical insulators and have excellent thermal conductivity. Flow type w m 2 k forced convection. The only difference between his ceramic heater and your normal electric heater is the element is probably wrapped around a ceramic core and this then heats up the outer plate whereas yours just has elements and relies on natural convection to. The heat convection coefficient the most important parameter for the convection process is dependent on not only the wind velocity the speed of air convection near the pavement surface but also the pavement surface characteristics roughness 189 190 189 190.

5 coefficient of thermal expansion 9 9 μm m c 6 specific heat capacity 460 j kg k 3. Convective heat transfer coefficients table chart the following table charts of typical convective convection heat transfer coefficients for fluids and specific applications.