Debonding Ceramic Brackets

The instrument s jaws and wedge are specially calibrated to the profile and base of the damon clear bracket resulting in a fast comfortable debonding experience for patients.

Debonding ceramic brackets. In group 1 clarity collapsible ceramic brackets 3m unitek monrovia calif were debonded. Debonding on the archwire the instrument seats at the center of each bracket half and over the archwire for a predictable debond. To debond position the instrument over the bracket firmly squeeze the bracket mesial distal to utilize. Ceramic brackets on the archwire.

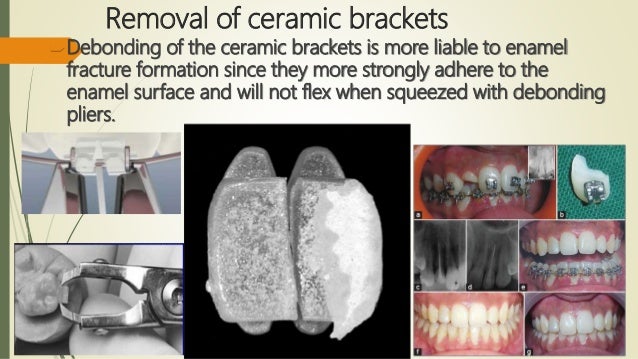

This study was conducted to compare the shear bond strengths patterns of bond failure and enamel surfaces after debonding two ceramic brackets clearvu and radiance plus and one standard metal bracket mini uni twin. Consequently the early ceramic brackets used a silane coupler required to act as a chemical mediator between the ceramic bracket base and the diacrylic or acrylic adhesive resin 4 6 12 13 chemical retention results in an extremely strong bond that may cause the enamel adhesive interface to be stressed during debonding 6 7 today there are. The mean shear bond strength of ceramic brackets is significantly greater than for metal. Thirty maxillary premolars were randomly assigned to one of two groups.

To test the null hypothesis that no difference in bracket failure characteristics is noted when use of a new ceramic bracket debonding instrument is compared with the use of conventional pliers. A remaining part of the ceramic bracket on enamel can be shaped in a way that it cannot be removed with pliers and. An additional risk for enamel damage is caused by the low fracture toughness of the ceramic brackets especially the monocrystalline brackets which may lead to break ups of the bracket itself during debonding 17 27 32. Intended for healthcare professionals.

The damon clear debonding instrument must be used to debond the damon clear bracket. Ceramic brackets are an esthetic alternative to metal brackets. The heat conductance of this material is volume 101 laser aided debonding of ceramic brackets 153 number 2 roughly 0 1 to 0 05 cal cmks for the temperature range of 0to 200c and has a linear expansion coefficient of ap proximately 6 7 10 6 k at 200c. No flash removal using a burr or scaler is required.